At Hindalco, we're more than just metal manufacturers – we're architects of possibility. Our manufacturing excellence and sustainability-focused approach to business have helped in positioning us as a leader within the industry.

Largest fully integrated aluminium manufacturing company in India

One of Asia's largest* producers of primary aluminium (*excluding China)

One of the largest custom copper smelters at a single location in Asia

Third largest manufacturer of copper cathode rods outside of China

Committed to manufacturing excellence

Our industry standing is a result of our commitment to excellence by design. We work continuously towards building products that enrich the lives of our customers by offering enhanced performance, increased convenience, and an overall superior experience.

Driving operational excellence

Digitalisation of process

ESG integration across the value chain

Downstream expansion in aluminium and copper

Alumina refining

Alumina produced at our Utkal (in Rayagada district of Odisha), Renukoot, Muri and Belagavi refineries is primarily utilised in the manufacturing of aluminium for our internal operations. Any excess alumina is sold to third parties as either standard alumina or specialty alumina. Our specialty alumina and hydrates have been developed by a dedicated research and development team at Belagavi. As a mines-to-market manufacturer, alumina refining is a critical step in Hindalco’s value chain as it enables us to maintain the quality of our products.

Our alumina refineries

Aluminium smelting

Our state-of-the-art aluminium smelters have a combined annual capacity of around 1.3 million tonnes of primary aluminium. We manufacture high-quality primary aluminium in the form of ingots, billets and wire rods which are used in a variety of industrial settings.

Our aluminium smelters

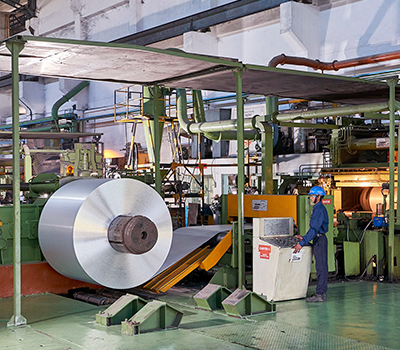

Aluminium downstream

As part of our downstream aluminium operations, we manufacture flat-rolled products, extrusions, foil, and packaging. We are committed to continue expanding our downstream value-added portfolio to serve the diverse needs of the market, especially high-growth segments such as electric vehicles, consumer durables, packaging, and batteries.

Our aluminium downstream

Hirakud FRP

Copper smelting

Our copper division, Birla Copper, is located in Dahej, Gujarat. It is home to one of the largest single-location copper smelters in the world, complete with integrated port facilities and the necessary logistical capabilities to efficiently meet the transportation needs of customers. Aside from our copper smelter, our Dahej facility comprises a captive power plant, oxygen plants, by-product plants, utilities, and a captive jetty. Our precious metals recovery plant extracts gold, silver, and selenium generated from the copper smelting process for sale in the market. In 2021, we expanded our copper downstream business by acquiring a 225,000-tonne continuous cast rod facility in Asoj, Gujarat.