How we make aluminium: From mines to market

Before our aluminium products enter the market, they go through a rigorous process that involves mining, refining, smelting and rolling.

The process of aluminium production begins with mining bauxite. Hindalco currently owns 27 bauxite mines spread across the states of Jharkhand, Odisha, Chhattisgarh and Maharashtra.

Once bauxite is mined, it is processed into alumina (also called aluminium oxide) using the Bayer process. We have alumina refineries located in Utkal, Renukoot, Muri and Belagavi.

Aluminium is extracted from alumina through the process of smelting. Hindalco’s aluminium smelters are located at Renukoot, Aditya Aluminium, Mahan Aluminium and Hirakud, producing 1.3 million MT of primary aluminium a year.

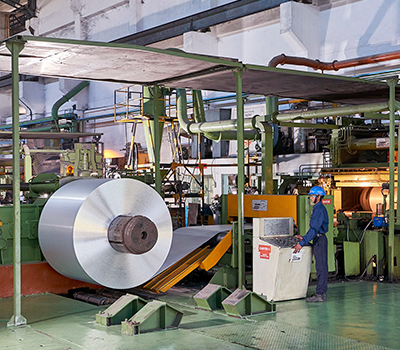

We dominate the aluminium downstream market with a production capacity of over 0.35 million MT. Our rolling facilities are located at Hirakud, Belur, Mouda, Renukoot and Taloja. Our extrusion plants are at Renukoot, Alupuram, Silvassa and Kuppam while our foil and packaging facilities are at Mouda and Silvassa.