We are India's premium supplier of foil used by businesses and end consumers alike for various packaging applications. Our kitchen foil brands, Freshwrapp and Superwrap, are household staples.

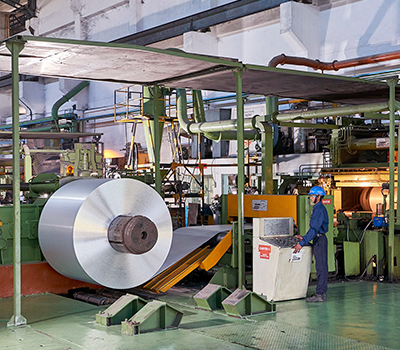

Hindalco is one of the leading manufacturers of foil used in various packaging applications by numerous industries, most notably the pharmaceutical industry. We have a state-of-the-art facility in Mouda dedicated to manufacturing foil with the latest technology that can meet a range of specifications. Hindalco has two well-known brands of aluminium foil in the market, namely Freshwrapp and Superwrap. All our foil products are manufactured using sustainable practices. Our unit at Mouda is also one of our eight units that are certified by CII as Single-use Plastic Free.

Our annual foil production capacity is over 28,000 MT, with our market share expected to rise to 15%. We are currently focusing on expanding our reach in value-added segments–including foil–to take advantage of the growing downstream market demand.

Foil offerings

Hindalco Priztec AluAlu foil

Our cold-formed blister packaging excels in creating deep cavities with superior lamination and bond strength. Ideal for sensitive pharmaceuticals and food products, our packaging is produced using food-grade lubricants and adheres to stringent quality and sustainability standards, including ISO, BRC, GreenPro and ASI certifications.

Blister and strip foil for pharmaceuticals

Our blister packaging offers superior print quality, lacquering speed and bursting strength, making it ideal for pharmaceutical applications. Compatible with various ink systems and printing techniques, our packaging is safe for sensitive medications and meets stringent child-resistant and senior-friendly requirements. Backed by comprehensive certifications, including ISO, BRC, IS16011, GreenPro and ASI standards, we deliver top-tier packaging solutions.

Flexible packaging foil for food & beverages

Our versatile film excels in high-speed lamination processes, offering exceptional barrier properties against moisture, gas, light and odours. it is ideal for a wide range of packaging applications, including confectionery, sachets, coffee capsules, pouches, lamitubes, dairy and beverage cartons. The film is compatible with various printing techniques and food-safe lubricants, ensuring product safety and quality. it is backed by comprehensive certifications, including ISO, BRC, IS15392, GreenPro and ASI standards.

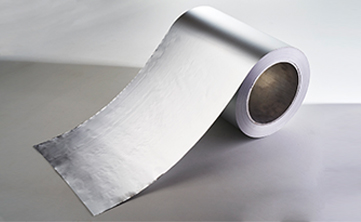

Household foil stock

Our aluminium foil is produced under strict controls, ensuring optimal hygiene for food contact applications. Its enhanced ultimate tensile strength allows for high-speed processing. Food-grade lubricants are used throughout the production process. Ideal for household and takeaway food packaging, our foil complies with rigorous quality and safety standards, including ISO, BRC, Kosher, Saber and GreenPro certifications.

Foil for lidding applications

Our aluminium foil is optimised for high-speed lid production, offering excellent compatibility with various lacquering and printing techniques. Designed for safe food contact, it utilises food-grade lubricants in the production process. Ideal for lidding applications, our foil meets stringent quality and sustainability standards and is certified by ISO, GreenPro and ASI.

Foil for Battery application

Our aluminium foil excels in delivering superior mechanical properties, high conductivity, exceptional surface cleanliness and flatness. Ideal for cathode current collectors in Li-ion batteries and pouch foil applications, it meets stringent industry standards. We are committed to quality, sustainability and automotive-grade excellence, as evidenced by our ISO, ASI and ongoing IATF16949 certifications.

Industries we serve

Hindalco’s aluminium foil and packaging solutions are well-established and serve the needs of several markets.

Read more

Our commitment to innovation

Hindalco’s R&D scientists have designed a new alloy called 3SRC to meet the market demand for stronger semi-rigid containers. This alloy has a higher strength percentage formability, lower energy footprint and uses a high amount of recycled content.

We have also solved the problem of the low ultimate tensile strength of our light gauge foils by modifying one of our rolling processes. This has resulted in higher-strength light gauge foils without compromising on other aspects. This new process is not only more energy-efficient but also allows us to scale our light gauge foil production for the export market.

Read more

For suppliers and vendors

For queries

Existing suppliers/vendors

Useful documents

Hindalco supplier code of conduct