The evolving transportation industry requires lightweight cargo vehicles, high load carrying capacity and better wear and tear resistance and decreased fuel consumption. Hindalco aluminium’s superior alloy composition and Specialty copper alloys meeting superior metallurgical properties and meeting stringent performance parameters are solution to it .

Hindalco aluminium’s superior alloy composition and metallurgical properties meet stringent performance parameters. Its high strength-to-weight ratio and excellent impact absorption qualities make it the best choice for transport vehicle components.

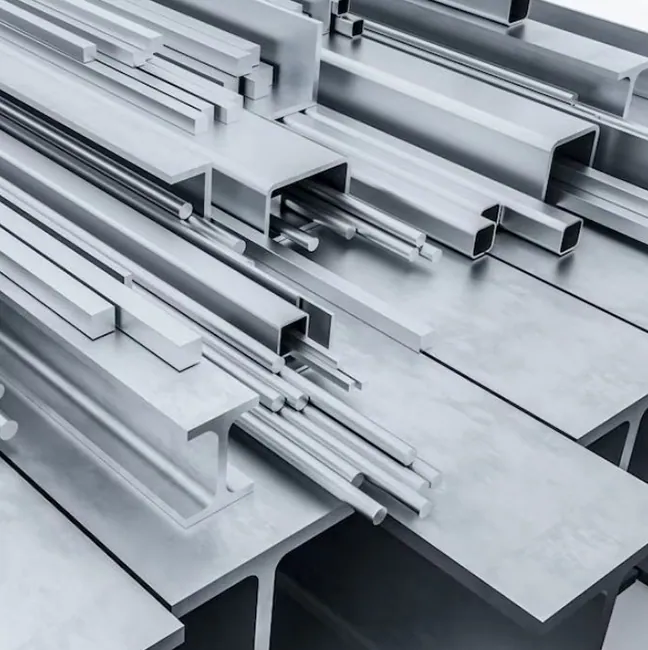

Our all-aluminium truck bodies, made of Hindalco’s extruded profiles, are lighter, more fuel-efficient and environment friendly. They also provide additional savings in terms of increased mileage and less engine and tyre wear and tear.

As one of Asia’s largest integrated primary aluminium producers and a leader in aluminium and downstream value-added products in India, we are extremely well-placed to provide lightweight aluminium and value-added solutions for commercial transportation. Our expertise is backed by superior Wagstaff AirSlip casting technology.

Specialty copper alloys: Hindalco’s innovation in developing specialty copper alloys improve their conductivity by approximately 102%, at the same time enhancing their strength, wear resistance and temperature handling ability. It makes the alloys ideal for metros and high-speed rail systems. Copper alloys are created by precisely blending refined copper with other metals, under tightly controlled conditions, with specialised equipment to enhance their electrical and physical properties. Hindalco is the first company in the world to produce 19.6 mm and 23 mm copper-silver (Cu-Ag) alloy using SMS Contirod technology, meeting the new demand for contact wires with superior tensile strength for high-speed railway networks.

By using the best technology available, i.e. Rautomead, we have produced copper-magnesium (Cu-Mg) alloy to meet railways and metros shift towards more sustainable Cu-Mg catenary wires, replacing existing copper-cadmium alloy. Our facility is also equipped to produce other copper alloys and oxygen-free electronic copper for a variety of applications. These advanced alloys are specifically designed to withstand high electrical loads, extreme environmental conditions, and mechanical wear and tear—making them the ideal material for constructing the contact and catenary wires used in high-speed trains and metro systems. These wires are essential for transmitting electrical power to the trains, ensuring their seamless operation. With the indigenisation of these critical materials, India now possesses the capability to supply world-class solutions for its rapidly expanding rail infrastructure, including both metro and intercity networks.

Our solutions