As India’s economy continues to grow, the demand for copper and aluminium is expected to skyrocket, driven by sectors such as building and infrastructure, green energy, data centres, packaging, automotive, construction, and industrial machinery. This surge is likely to double the country’s aluminium consumption to approximately 10 million metric tons over the next decade, while copper demand is expected to reach 2 million metric tons by 2030 and 5 million by 2047. Aluminium’s exceptional properties, including corrosion resistance, a high strength-to-weight ratio, and non-pyrophobic nature, make it a preferred material for a diverse range of industrial applications. Its malleability and formability further enhance its versatility. Copper’s excellent electrical and thermal conductivity, malleability, ductility, strength, durability, recyclability, and corrosion resistance, along with its excellent alloying properties, make it widely applicable in industrial machinery.

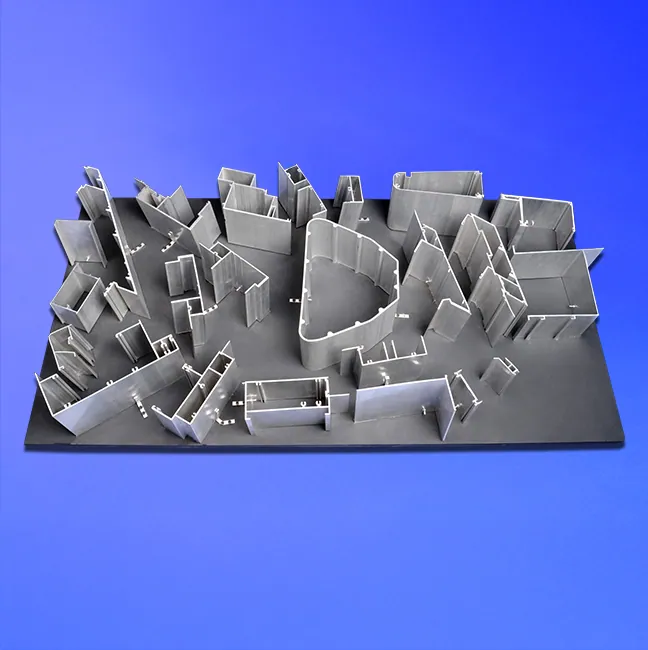

Our solutions