Key benefits

Superior high-temperature resistance and chemical stability

Consistent quality through stringent process control

Tailored solutions based on 50+ years of industry experience

Commitment to sustainability and Make in India initiative

Hindalco offers a comprehensive range of high-performance alumina solutions tailored for the Refractory industry. Leveraging 50+ years of expertise and mines-to-market fundamentals, we provide consistent, high-quality alumina products with superior heat resistance and chemical stability.

Our customised solutions address diverse refractory needs, from coarse to sub-micron alumina, with stringent control of critical parameters like crystal size, specific surface area, particle size distribution, soda as well as other impurities. Committed to sustainability, we drive innovation to contribute to energy conservation, environment protection, and recycle and waste management.

Our PrizTec refractory solutions are innovative alumina solutions for elevating refractories with unparalleled durability, heat resistance and corrosion protection for high-performance applications.

Hindalco introduced FUSALOX™, white fused alumina, imparting properties of exceptional heat resistance, purity and reliability. Ideal for precision abrasive applications, advanced refractories and advanced ceramics, FUSALOX™ is manufactured with precision technology. Hindalco is constructing a world-class WFA plant in Odisha, India, with an initial capacity of 60,000 tonne per annum. It is scheduled to commence operations in FY26.

Superior high-temperature resistance and chemical stability

Consistent quality through stringent process control

Tailored solutions based on 50+ years of industry experience

Commitment to sustainability and Make in India initiative

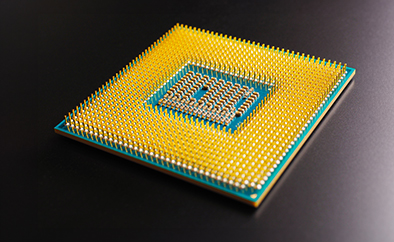

The grades of unground alumina, with various controls, are used in various refractory applications such as production of high alumina cement and synthetic aggregates

Hindalco ground alumina solutions with d50 ranging from 3 to 5 microns are used in both shaped and unshaped products

This customised grades of alumina with coarser d50 ranging from 4 to 5 microns with a wider particle size distribution are suitable for use in ramming masses and continuous casting refractory applications

High degree of calcination, with four times lesser soda than regular alumina, controlled particle size, suitable for applications with higher requirements for thermal stability

Monomodal, bimodal and multimodal alumina. Pre-defined particle packing, rheology, consistent placement characteristics and superior hot and cold properties. Suitable for slide gate refractories, self-flow castable, iron-runner castable, abrasion resistance products, and shotcretes applications

Highly reactive sub-micron alumina, having higher specific surface area, is used mainly for technical ceramics and high alumina castables

It is a precisely engineered product with an impressive 99.4% purity and dense non-porous microstructure; fused at temperature of 2,000 degree celsius for exceptional strength and versatility

Hindalco supplier code of conduct