Leading copper rod supplier to the Indian Railways

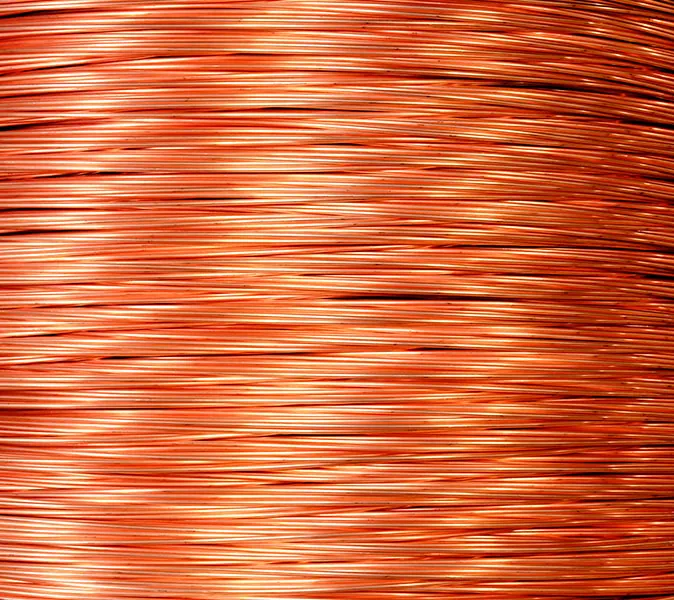

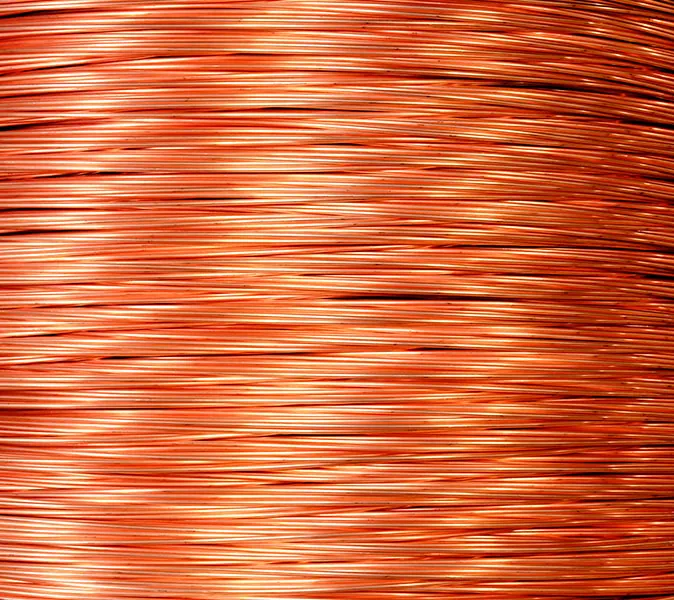

Our copper ETP rods (8 mm - 26 mm) are made from electrolytically refined copper cathodes, made with state-of-the-art production technologies from Southwire, USA, and Contirod, Germany. We ensure that our rods meet the highest standards for all downstream applications, guaranteeing optimal performance and reliability.

USP/benefit: Engineered for optimal electrical conductivity and high reliability, Hindalco’s rods enhance efficiency across electrical energy generation, transmission and distribution.

Certifications: Our copper ETP rods comply with all international standards set by ASTM-49, BS EN 1977 and IS 12444, ensuring quality and reliability across all applications. Additionally, Hindalco’s larger diameter rods—19.6 mm, 23 mm and 26 mm—are approved by the Research Design and Standards Organisation, making them the preferred choice for electrifying railway networks.

Applications:

Birla Copper has a dedicated team at its Dahej copper facility that specialises in conducting research and development related to copper smelting, copper refining and by-product applications. In line with our sustainability goals, we have recently modified our copper rod production process to make it more energy-efficient. This has enabled us to reduce our LNG consumption by 6.4%.

Read more

Hindalco supplier code of conduct