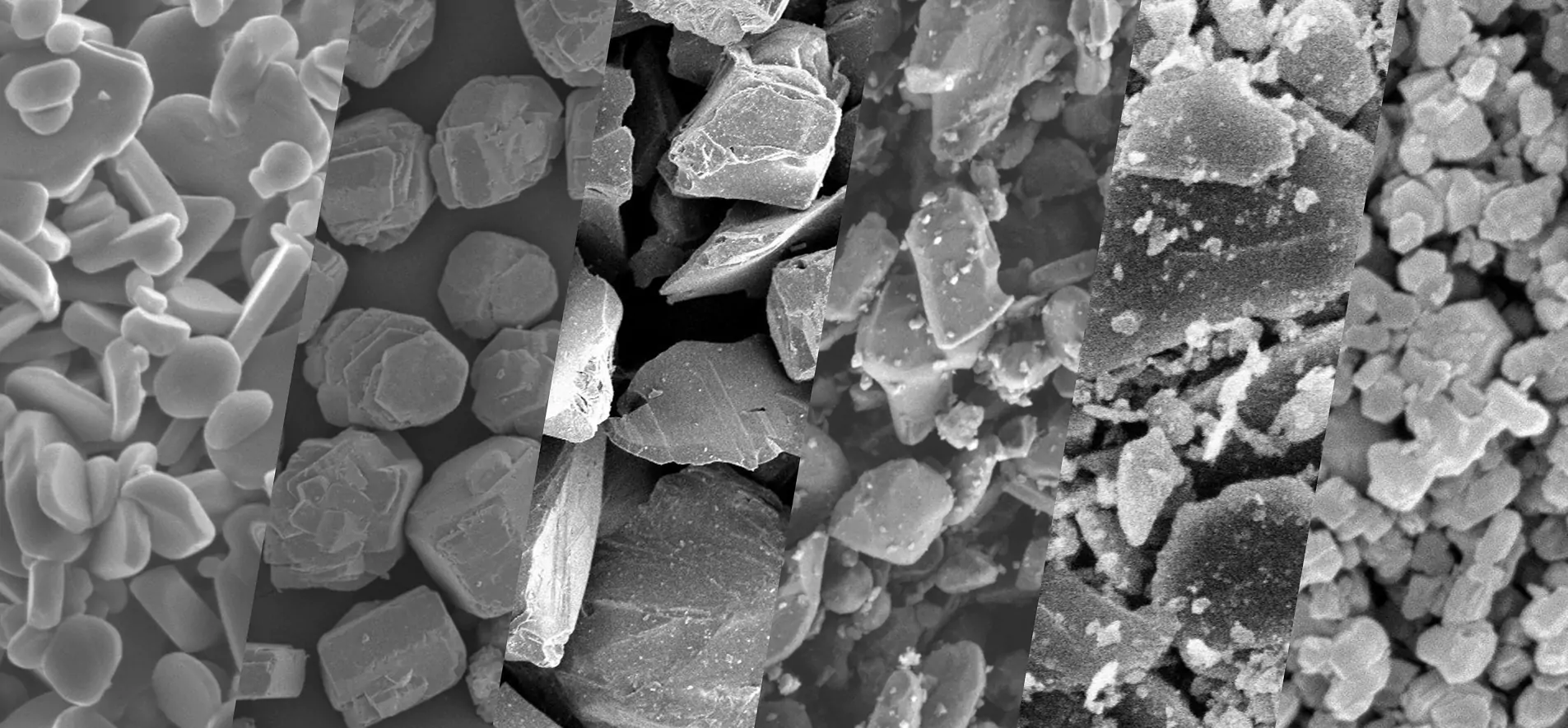

Specialty Hydrate Products

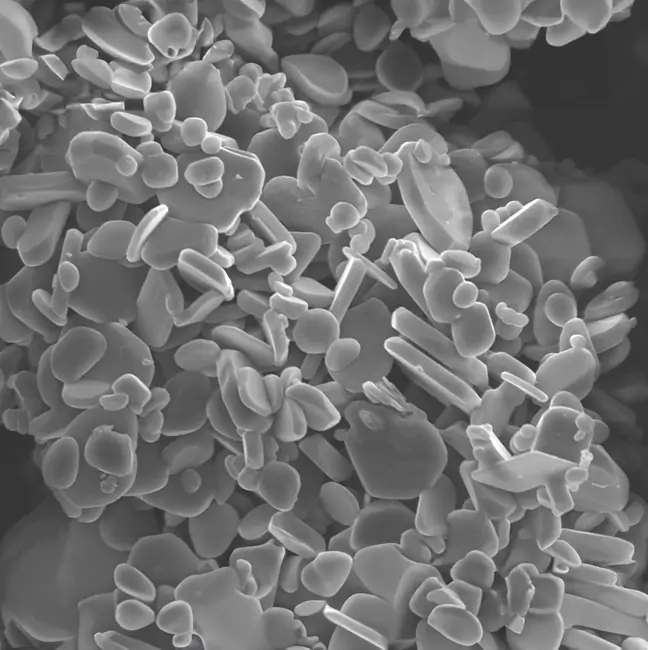

Wet hydrate

Hindalco's wet hydrates are unground alumina hydrates used primarily as raw materials in various industrial processes. These hydrates possess upto 7% moisture content. This hydrate are essential in the production of aluminium-based chemicals like aluminium sulphate and poly aluminium chloride. Wet hydrates are also used in the manufacture of glass and activated alumina due to their chemical properties.

Applications

- Water Treatment Chemicals: Aluminium Sulphate and Poly Aluminium Chloride (PAC) used in water purification for coagulation and flocculation, helping to remove impurities from water.

- Production of aluminium Compounds like Aluminium Fluoride: used as an essential compound in the production of aluminium by electrolysis.

- Ceramics and Glass Manufacturing: Acts as a source of alumina in glass formulations, improving the chemical durability and physical hardness of glass.

- Catalyst Production like activated Alumina used as a desiccant, in water purification, and as a catalyst or catalyst carrier in various chemical reactions.

Dry hydrate

Dry hydrates from Hindalco are characterized by their low moisture content, making them suitable for dry processing environments. These hydrates are used extensively in the production of alumina chemicals, heat-resistant glass, additive in plastics as flame retardant and production of activated alumina, which is used for water purification and as a catalyst carrier. The physical and chemical stability of dry hydrates ensures their effectiveness in various industrial applications. Like wet hydrates, they are non-flammable and non-explosive, ensuring safety in handling and usage.

Applications

- Heat-resistant Glass: Provides thermal resistance and durability in high-temperature applications such as furnace windows and cookware.

- Ceramic Industries: Used to impart mechanical strength and thermal resistance to ceramic products.

- Chemical Industry: Dry hydrates serve as raw materials for producing various alumina-based chemicals which are integral in numerous chemical processes and products.

- Catalysis and Adsorbents: utilized in the adsorption of unwanted gases and liquids. Also used as a catalyst in the production of polyethylene.

- Catalyst Carriers: Provide a large surface area for catalysts, improving the efficiency and selectivity of chemical reactions.

- Fillers in Plastics and Composites: Used as a filler to enhance the properties of composites, such as fire retardant and mechanical strength.

- Fire Retardant Applications: Incorporated into plastics and rubbers to improve fire resistance, crucial for safety in automotive and construction materials.

Grades Used- Dry Hydrate grades, DH50, UWDH, TP

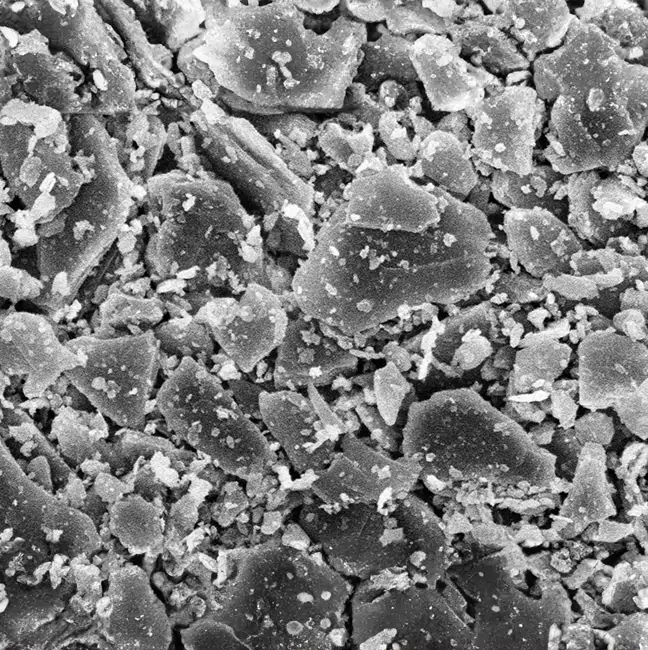

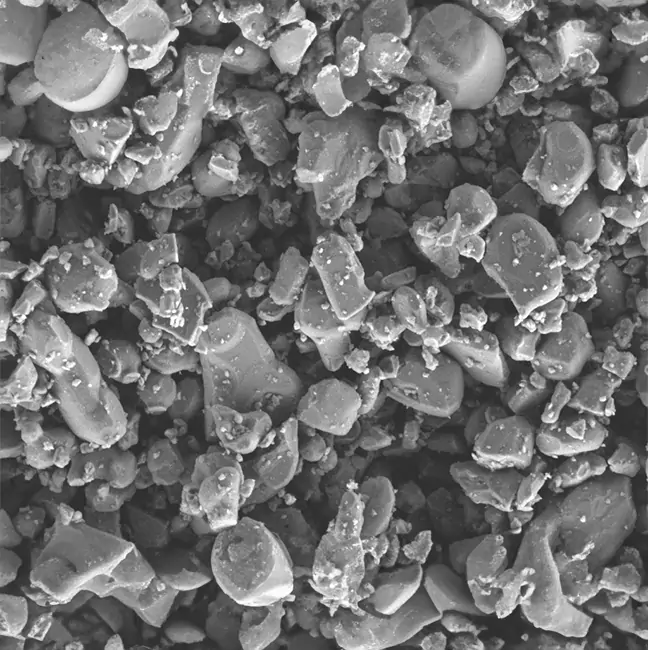

Ground hydrate

HINDALCO's Ground Hydrate is characterized by a specific moisture content, variable particle size distribution, and a controlled chemical composition. This hydrate is ideal for applications requiring specific physical properties, such as particle size, distribution, oil absorption, viscosity etc. It's manufactured with stringent quality control, ensuring consistency in its physical and chemical properties. The ground hydrate is offered in several grades to meet different industry needs, emphasizing its versatility in various applications.

Applications

- Utilized in the manufacture of solid surfaces.

- Used for cable compounds, dough moulding compounds, sheet moulding compounds, cable compounds, rubber conveyor belts, potting application, resin transfer moulding compounds.

- Used for pultrusion compounds, PVC, catalyst carriers.

Grades- RPF14, UWRPF14, RPF18, DHM, UWDHM, DHM15, UWDHM15, FH22D, FHC, MHV06, MHV20, UWMHV20, TH15, LVH20, DHM06, SF300, SF400

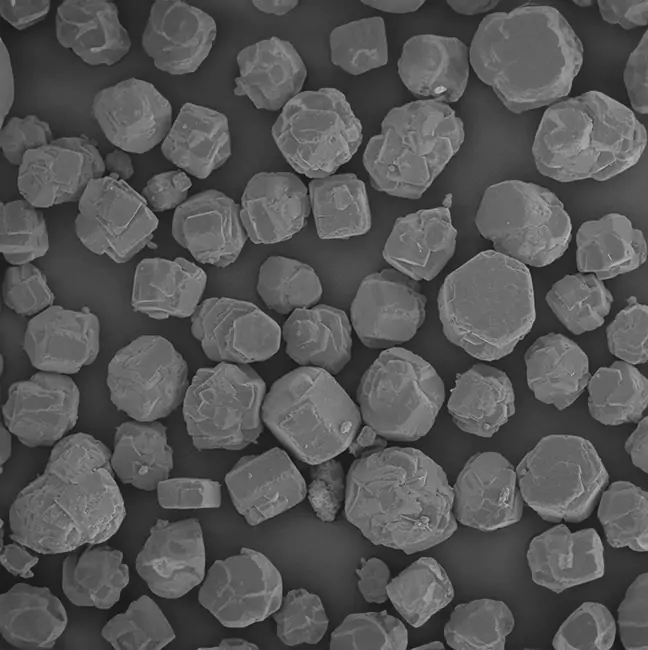

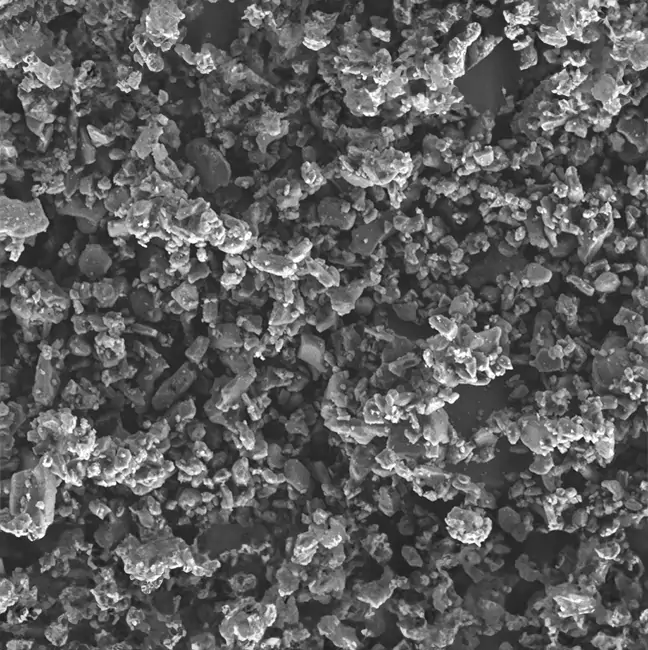

Precipitated hydrate

HINDALCO’s superfine Precipitated Hydrate is engineered for specialized applications that demand high purity and precise particle size control. This product is noted for its exceptional consistency in quality and performance, making it highly suitable for industries where precision is crucial. The precipitated form allows for enhanced reactivity and purity, facilitating its use in more technical and sensitive applications

Applications

- Used at functional additive in HFFR cable compounds

- Used as a fire-retardant additive in plastics and rubber.

- Serves as a filler and coating agent for different polymer and water based products.

- Employed in the production of titanium dioxide for paints and coatings.

Grades- SFH105VS, SFH108VS, SFH105, SFH108, SFH105P, SFH108P, SFH105 SA , SFH108SA

Boehmite

Boehmite is an aluminium oxide-hydroxide known for its exceptional properties, including high-temperature stability and resistance. This material is utilized in various high-demand applications. Its environmental safety attributes align with current trends toward greener manufacturing processes, enhancing its appeal in industries shifting towards sustainable practices.

Applications

- Critical in enhancing the safety and performance of lithium-ion batteries by reducing the risk of short-circuits.

- Serves as a flame retardant in electrical and electronic components, including printed circuit boards.

- Employed in the production of coatings, ceramics, and polymers that require stability at high temperatures.

- Acts as a functional filler in plastics and ceramics, improving material properties for industrial use.

Specialty Alumina

Coarse

HINDALCO presents coarse calcined alumina with diverse chemical and physical properties, offering unique feature combinations that are imperative for various application segments. Hindalco Alumina exhibits soda content ranging between 0.03 to 0.35% and the specific surface area between 0.4 to 75 m²/g, available in various particle shape and sizes.

Applications

- High alumina cement production

- Synthetic aggregates

- Insulations bricks production for furnace or kiln lining

- Technical Ceramics

- Essential Ceramics

- Catalyst

- Adsorbents

Grades: A, B, SX, G, HT, IC03, IC10, HCA3, HCA4, and GMU35

Ground

Hindalco offers fine ground and super ground alumina with unique particle distributions and different chemical properties. It is available in various grades with different levels of soda content and defined specific surface area for meeting various applications.

Various grades series have a sodium oxide content typically ranging from 0.1% to 0.35%. The specific surface area (SSA) ranges from 0.9 to 1.2 m²/g, and the particle size distribution (PSD) D50 ranges from 3 to 5 microns.

Special grades series are designed with a wider particle size distribution, having a D50 between 4 and 5 microns.

Ground aluminas are used in applications such as glass/frits, Wear ceramics, refractories, brake pads and polishing. PG series of alumina are special grades exclusively for polishing applications. HCASG/HCAFG, ICSG/FG series of alumina are advanced grades with superior soda control and narrow particle distributions which helps meeting advanced ceramics and refractory applications.

The ground series of alumina enhances bulk density by better packing fraction and controlled pore size distribution. This elevates the performance such as thermal conductivity, electrical resistivity, thermal shock resistance, creep resistance, wear resistance, flexural and compressive strengths in ceramics and refractories. These properties are governed by the controlled particle size distribution and degree of crystallinity; with control on feedstock- Hindalco makes ground alumina versatile for various applications.

Reactive Alumina

Hindalco's reactive alumina is tailored to produce high-performance refractories and advanced ceramic products with defined particle packing, rheology, consistent particle characteristics. Our reactive aluminas, with SSA (m²/g) ranging from 3 to 12, are categorized into monomodal, bimodal, and multimodal types with pre-optimized particle size distribution to enhance packing factors in matrices, reducing pore sizes and volume, and providing superior thermo-mechanical properties.

Our monomodal reactive alumina (SMA series) has soda content ranging from 0.01% to 0.1% and mean average size between 0.4 to 0.6 microns. The bimodal (MRB series) and multimodal (MRM series) reactive alumina grades have sodium oxide content ranging from 0.06% to 0.15% and D50 between 0.8 to 2.5 microns.

Critical end-uses

- Slide gate refractories

- Self-flow castable

- Iron-runner castable

- Gunning

- Shotcreting

- Porous plugs

- Ceramic rollers

- Ceramic tubes

- Ceramic substrates

- High purity liners for petrochemical industries

FUSALOX™ White Fused Alumina

Our white fused Alumina, FusaloxTM has unique properties like toughness, chemical purity and high refractoriness. Considering the refractory usage, other than the mentioned properties, superior abrasion resistance, excellent creep & corrosion resistance makes FusaloxTM a material of choice.

Major Applications include:

- Creep resistance bricks manufacturing

- Glass channels and feeders

- Chemical resistance bricks

- Petrochemical industry bricks

- NRM

- Cement plant refractories