Specifications

Everlast, a Hindalco brand, launched in December 2002, is made of aluminium and is ideal for all roofing and cladding needs. It is easy to use, durable and economical to work with. Using aluminium for roofing has many benefits. Some of them are the following:

- Aluminium roofing sheets are extremely light and have a high strength-to-weight ratio.

- Aluminium is an increasingly popular choice for use in installations and buildings. It is corrosion-resistant in almost any kind of environment. Even in highly corrosive industrial environments, it is resistant to fumes and vapours of organic compounds and to chemicals like ammonia, carbon dioxide and acids such as hydrochloric acid, nitric acid and sulphuric acid. Such corrosion resistance gives the metal a long life and keeps it looking good throughout its life.

- The shine and brightness of aluminium livens its surroundings, and, because it doesn't stain, discolour or rot, it keeps its brightness and shine for a long time. Aluminium corrugated sheets can take a variety of finishes, colours and textures, which protect them and further enhance their appearance.

- An aluminium structure can be easily dismantled, transported and re-assembled in a new location.

- Though the metal is a good conductor of heat, its high reflectivity for radiant heat and light (75 to 80 per cent when new, 60 per cent after several years) keeps the interiors of aluminium building from five to eight degrees celsius cooler in summer, while its low emission rate cuts heat loss in winter.

- It is easy to maintain and wash.

Physical properties

| Alloy (AA) |

Temper |

UTS (mpa) |

Yield stress

(0.2% proof stress) |

Elongation %

|

| Min |

Max |

| 3003 |

H18 |

170 |

- |

165 |

1 |

| 3105 |

H18 |

190 |

- |

165 |

1 |

| 8011 |

H18 |

175 |

- |

165 |

2 |

Chemical composition (%)

|

Alloy (AA)

|

Al

|

Cu

|

Mg

|

Si

|

Fe

|

Mn

|

Zn

|

Ti

|

Cr

|

Remarks

|

|

8011

|

Remainder

|

0.20

|

0.10

|

0.60 — 0.95

|

0.60 — 0.95

|

0.10

|

0.20

|

0.20

|

0.20

|

-

|

|

3003

|

Remainder |

0.10

|

0.10

|

0.60

|

0.70

|

0.80 — 1.20

|

0.20

|

0.20

|

-

|

-

|

|

3105

|

Remainder |

0.30

|

0.20 — 0.80

|

0.60

|

0.70

|

0.2 — 0.8

|

0.40

|

0.10

|

0.20

|

-

|

|

5052

|

Remainder |

0.10

|

1.70 — 2.60

|

0.60

|

0.70

|

0.50

|

0.20

|

-

|

0.25

|

Cr+Mn=0.50

|

Other typical properties

|

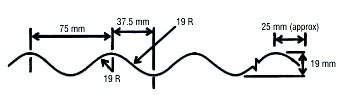

Circular corrugated sheet

|

0.30 — 1.22 mm

|

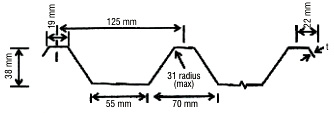

| Industrial troughed sheets |

0.40 — 1.63mm

|

| Curvomatic troughed sheets |

0.40 — 1.22mm

|

Width

Hindalco's aluminium sheets are available in the following widths (unit mm):

| Troughed

|

Overall

|

Effective

|

| Ind. 6 |

795

|

750

|

| Ind. 7 |

920

|

875

|

| Ind. 8 |

1044

|

1000

|

| Circular corrugated

|

Overall

|

Effective

|

| 10/3 |

800

|

750

|

| 16/3 |

1250

|

1200

|

| 12/3 |

950

|

900

|

Length

Between 1500 to 6500 mm. Other lengths may be provided on request.

Young's Modulus

Young's Modulus or modulus of elasticity for aluminium is 7.0x104 mpa.

Finish

Everlast is available in mill and stucco finish. Colour coated sheets can be provided on request.

Curvomatic and tiled profile sheets are offered.

Workability

Everlast can be bent to the required shape. It is subject to the bend radii of the alloy.

Troughed sheets

Thickness

(mm)

|

Kg/Sq.m.

|

Kg/m

|

Section modulus

(Z) per pitch mm3

|

Moment of inertia

(I) per pitch mm4

|

|

Ind-6 (795mm)

|

Ind-7

(920mm)

|

Ind-8 (1044mm)

|

|

1.20

|

4.33

|

3.43

|

3.97

|

4.50

|

1739

|

41383

|

|

0.90

|

3.23

|

2.56

|

2.96

|

3.36

|

1310

|

31099

|

|

0.70

|

2.50

|

2.00

|

2.31

|

2.62

|

1037

|

24379

|

|

0.65

|

2.31

|

1.83

|

2.12

|

2.41

|

952

|

22346

|

|

0.55

|

1.96

|

1.57

|

1.82

|

2.07

|

823

|

19296

|

Permissible loading

|

Purlin spacing L(mm)

|

1.22mm

|

0.91mm

|

0.71mm

|

0.56mm

|

|

914

|

|

1066

|

507

|

636

|

505

|

|

1245

|

943

|

743

|

590

|

|

1219

|

|

600

|

454

|

357

|

284

|

|

700

|

530

|

418

|

332

|

|

1524

|

|

384

|

290

|

229

|

182

|

|

448

|

339

|

267

|

212

|

|

1829

|

|

266

|

202

|

159

|

126

|

|

311

|

236

|

186

|

148

|

|

2134

|

|

181

|

136

|

106

|

84

|

|

229

|

173

|

136

|

108

|

Circular corrugated sheets

Thickness

(mm)

|

Kg/Sq.m.

|

Kg/mtr

|

Section Modulus

(Z) per pitch mm1

|

Moment of Inertia

(I) per pitch mm4

|

10/75

(1250 mm)

|

18/75

(950 mm)

|

10/75

(800 mm)

|

|

1.20

|

3.72

|

4.71

|

3.66

|

3.01

|

462

|

4670

|

|

0.90

|

2.77

|

3.51

|

2.68

|

2.25

|

348

|

3466

|

|

0.70

|

2.14

|

2.74

|

2.09

|

1.75

|

274

|

2697

|

|

0.65

|

1.98

|

1.59

|

1.89

|

2.49

|

251

|

2469

|

|

0.55

|

1.68

|

2.16

|

1.65

|

1.38

|

217

|

2123

|

|

0.45

|

1.38

|

1.10

|

1.31

|

1.72

|

175

|

1704

|

|

0.35

|

1.07

|

0.85

|

1.02

|

1.34

|

137

|

1321

|

Permissible loading

|

Purlin spacing L(mm)

|

1.22mm

|

0.91mm

|

0.71mm

|

0.56mm

|

|

914

|

|

432

|

321

|

250

|

197

|

|

551

|

416

|

327

|

259

|

|

1219

|

|

182

|

135

|

105

|

83

|

|

310

|

234

|

180

|

146

|

|

1524

|

|

93

|

69

|

54

|

43

|

|

197

|

150

|

118

|

93

|

|

1829

|

|

54

|

40

|

31

|

25

|

|

129

|

96

|

74

|

59

|

|

2134

|

|

34

|

25

|

20

|

16

|

|

81

|

60

|

47

|

37

|

Applications

- Cladding for roofs and walls

- Industrial buildings, warehouses, aircraft hangers

- Indoor and outdoor stadiums

- Insulation and protection of fuel storage tanks and industrial boilers

- Wall panels for high-rise buildings

- Residential roofing

- Roof-on-roof roofing

- Exhibition pavilions

- Poultry farms

- False ceilings